Despite all of the clear benefits however, RFID can still be confusing at a technical, deployment level. How exactly does it work in a global manufacturing context? Is RFID durable? Is it secure? Let’s answer some of these questions, using as an example Ultra High Frequency (UHF) passive RFID labels, also known as RAIN RFID labels.

Global tracking made easy

RFID readers are set to the relevant country’s frequency, therefore making them applicable to that region. Each country defines its frequency standards; however, most RFID labels are designed for global use. Some particular RFID label designs, such as on-metal tags, can be tuned for regional frequencies.

Benefits versus limitations

RFID labels do face technical challenges in certain environments. For example, metal surroundings or other radio waves can affect RFID read range. This is because RFID labels are passive, and they will reflect (backscatter) the radio waves they receive from an automotive RFID reader. Metal, concrete walls or other radio waves can affect or even block the signal from the reader or label and have an influence on readability and read range. Despite these constraints, the benefits of automotive RFID labels still far outweigh their limitations.

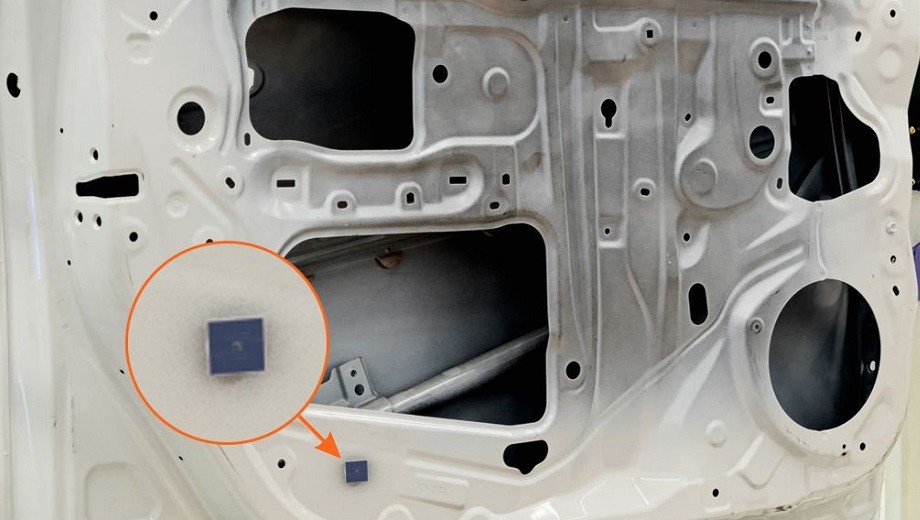

And in most cases, we can find workarounds that allow the labels to work appropriately. For example, by carefully positioning and tuning the reader’s signal, you can ensure it is not blocked or is in any way interfered with. By using FlagTag or foam tags on a metal surface, we make sure that the tags can backscatter without signal disturbance.

Can data encoded on an RFID tag be trusted?

Normally, anyone can encode information on the silicon chip embedded in RFID labels or tags by adding to or overwriting previous data. However, some chips offer the possibility of locked memory banks and digital signature creation. In addition, the unique tag ID number, which is stored in the TID (tag ID) memory block, cannot be changed by anyone.

Avery Dennison Smartrac offers a variety of security options best suited for applications which require high read range and that demand an extended user memory to store data. OEMs can encrypt the information, but they have standard formats on how they save data.

Batch reading for maximum efficiency

In most situations, an RFID reader will read all RFID tags within a specific range or area as one batch. The reader will recognize all individual unique ID codes in a split second.

The tag uses the reader signal to power up and respond to a request for the data. The tag then modulates, or regulates, the carrier signal from the reader and reflects (backscatters) the signal. This low-amplitude signal is detected and decoded by the reader.

Reader deployment and range depend on the environment

A separate reader is needed in each area in your facility where you would like to create a reading point. Most RFID labels have a read range of 10 meters or more, provided nothing interferes with the radio signals; but for every reading point, you must fine-tune the reader to the optimum settings. Sometimes this involves reducing the power and the reading range.