Window seals, weather stripping and body seams are the primary causes of factory water leakage inside cars. Those leaks will soon become a thing of the past, as Avery Dennison Smartrac launched the first-ever passive water sensor that works on metal surfaces like the harsh environment of an automobile chassis. The solution is successfully being tested in high-end OEM cars, ensuring that cars leaving the factory are completely watertight, and may also find further industry applications in aviation manufacture, shipbuilding or liquid packaging.

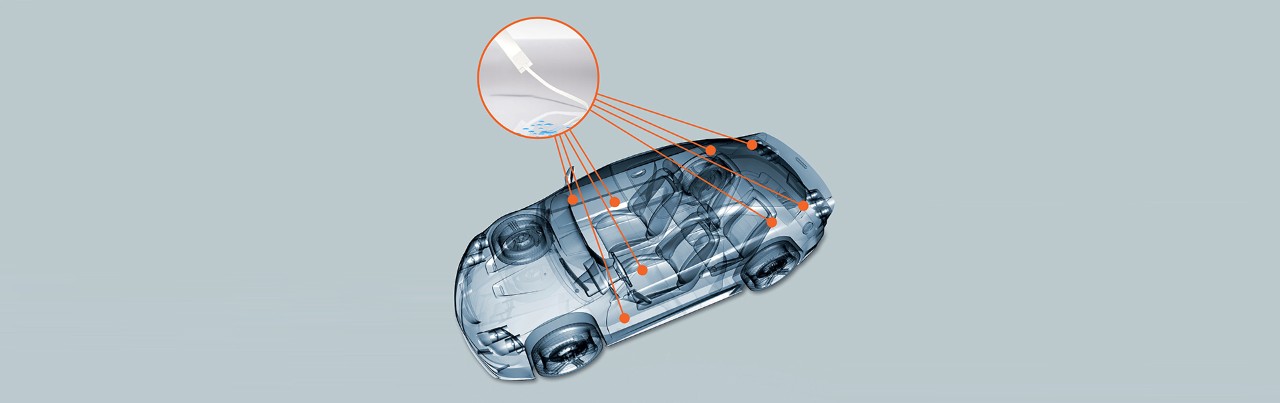

Avery Dennsion Smartrac has teamed up with chip manufacturer RFMicron to develop a passive UHF sensor tag that is deployed inside cars during assembly. It can detect even small amounts of water leakage inside vehicle compartments, protecting the car from water leakage that can damage the electronics bays, cabins and trunks. This is becoming ever more important for manufacturers, as more and more hybrid and electric cars are produced that require enhanced protection for their electronic circuitry and electrical components.

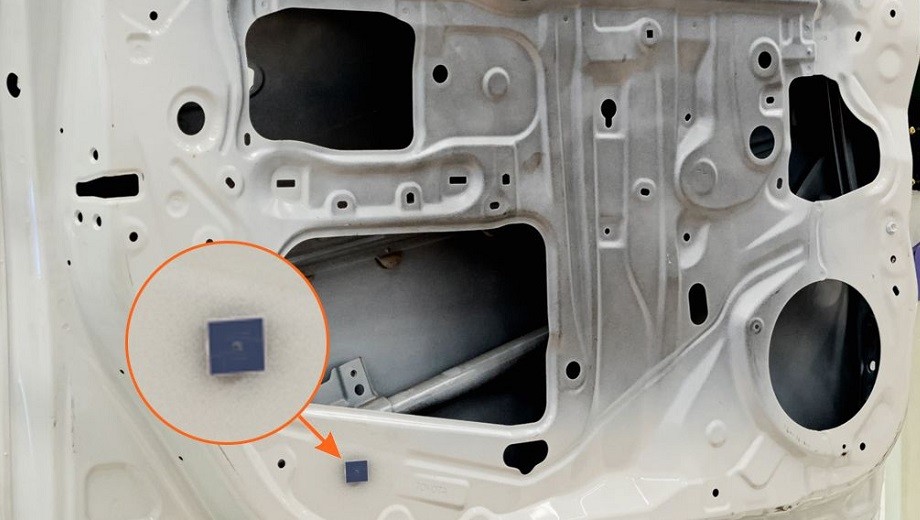

Avery Dennison Smartrac’s Sensor Tadpole tag works flawlessly on metal surfaces, with minimum signal degradation from surrounding structures. The on-metal passive sensor tag has a strong adhesive and small, slim form factor, which makes for easy deployment on difficult surfaces. The detection area can be extended by using a wicking tail that guides moisture to the sensor tag. This enables even minute amounts of water to be detected quickly, easily and reliably, allowing manufacturers to identify the source of a leak.

The use of a passive sensor means that the tag requires no power source, servicing or replacing. The energy comes from the hand-held reader, or optionally from a gate reader, which scans vehicles as they pass through the final quality-check areas of the factory production line.

“The use of RFMicron’s Magnus® S2 Sensor IC enables a reliable alternative to today’s manually intensive and error-prone water intrusion testing process with an automated, cost-effective, scalable moisture-sensor solution” said Shahriar Rokhsaz, President and CEO of RFMicron. “The benefits of the sensor solution are cost savings, faster and more accurate water intrusion detection and improved customer satisfaction, as vehicles that escape factory water intrusion testing result in significant field repair costs and cause irreparable damage to a manufacturer’s reputation.”