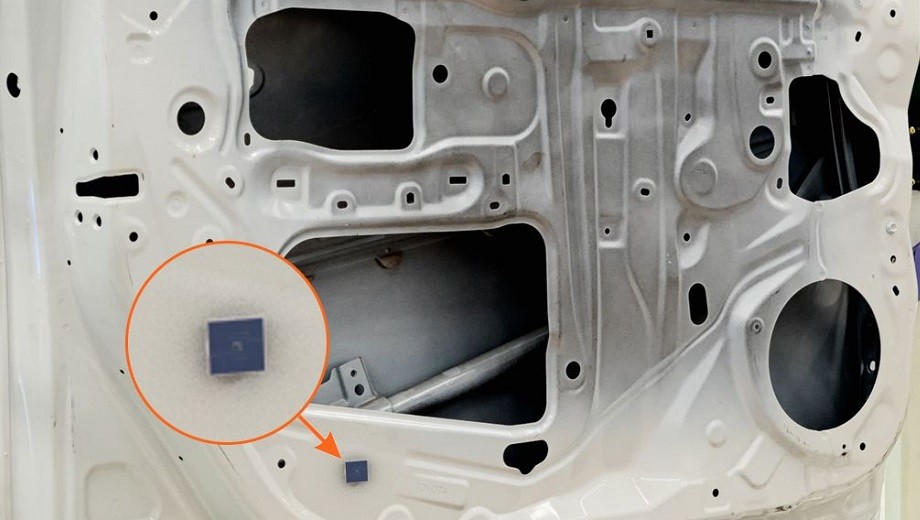

Additionally, Fast Group is looking for sustainable solutions by replacing disposable packaging with recyclable circulation trays. After the upgrade, a unique ID card carrying various kinds of internal management information will be bound to the recyclable circulation tray of the corresponding part. With the terminal in hand, an inventory can be made and goods can be found immediately.

In the past, goods in process and raw materials greatly relied on manual data capture with pen and paper. The adoption of RFID has resulted in reduced manual labor by 30%, an uplift of inbound and outbound efficiency by 30%, and improved inventory accuracy equally by 30%, in real-time.

Over the past two years since the start of project deployment, it has been verified that each RFID tag can be used over 200 times annually, which is in compliance with Fast Group’s sustainability goals.

The Fast Group RFID hub links up the business systems of intelligent manufacturing to achieve data interconnectivity, which improves the management efficiency and realizes all-dimensional visualization of information.

From this successful RFID implementation, the management of Fast Group saw significant improvements within their processes. At present, Fast Group has joined hands with MetTech and Avery Dennison Smartrac to actively expand the application across all their digital led processes and applications.

“It is a great honor for us to assist industry leaders like MetTech and Fast Group in the exploration and implementation of supply chain digital transformation, and contribute to sustainable development in China. As a key solutions enabler across the entire supply chain, Avery Dennison Smartrac is committed to sustainability and products that minimize impact on the environment. We have set ambitious sustainability goals for 2030. In addition to self-optimization, we help our upstream and downstream ecosystem partners to reduce carbon emission and reduce waste,” said Lynn Lu, Senior Market Development Manager, Avery Dennison Smartrac.

Please watch the video for more information.