By Tyler Chaffo, Manager of Global Sustainability, at Avery Dennison Smartrac

Over the past year I’ve had the chance to speak to a variety of senior business and sustainability leaders about supply chain topics and their implication in a range of ESG issues. What is apparent from these conversations is that the supply chain is increasingly considered to be one of the most impactful components of a company’s sustainability efforts.

This trend is also echoed by initial findings revealed at the UN Global Compact Leaders Summit in June, which showed that 50% of companies globally say that supply chain sustainability has grown in importance since the COVID-19 pandemic.1

Perhaps not surprising when we consider increased public attention following high profile incidents, from poor labor conditions behind some of the world’s best-known fashion brands to a Greenpeace petition against the world’s biggest online retailer to end unsold goods being destroyed. Consumer, investor and shareholder pressure is mounting and so too is regulatory pressure.

Regulatory requirements have been a catalyst in moving ESG up the agenda for many years with initiatives such as Extended Producer Responsibility (EPR) policy being particularly important. The recent introduction of Germany’s supply chain act is a notable milestone. Under the act, companies in Germany above a certain size must establish due diligence procedures that prevent human rights and environmental abuses within their global supply chains. It also forces large companies to pay fines of up to 2% of their annual global turnover if they violate the rules, as well as exclusion from public tenders.

We can expect to see increased scrutiny and further demands for transparency from multiple stakeholder groups, which will serve to push deeper levels of sustainability into supply chain practices. In the UK, the Competition and Markets Authority (CMA) announced that it was investigating the impact of green marketing on consumers, while in the US, a study of 2,000 US consumers shows that 31 percent would support a “fast-fashion tax” for companies on clothing that’s unsustainable.

The focus on supply chain issues will only intensify, and the expectation from leaders to familiarize themselves with how their companies are managing their supply chains across first-tier and lower-tier suppliers is not going away. To help navigate this new business paradigm, here are four key strategies to consider:

Focus on Transparency. Modern-day supply chains are a complex web, which means there are often many knowledge gaps in information flow. For many companies, the pandemic revealed a worrisome lack of full visibility into their supply chains and exposed poor practices. It’s important to identify your operational weaknesses among first-, second- and third-tier suppliers to ensure proper oversight and management of supply chains.

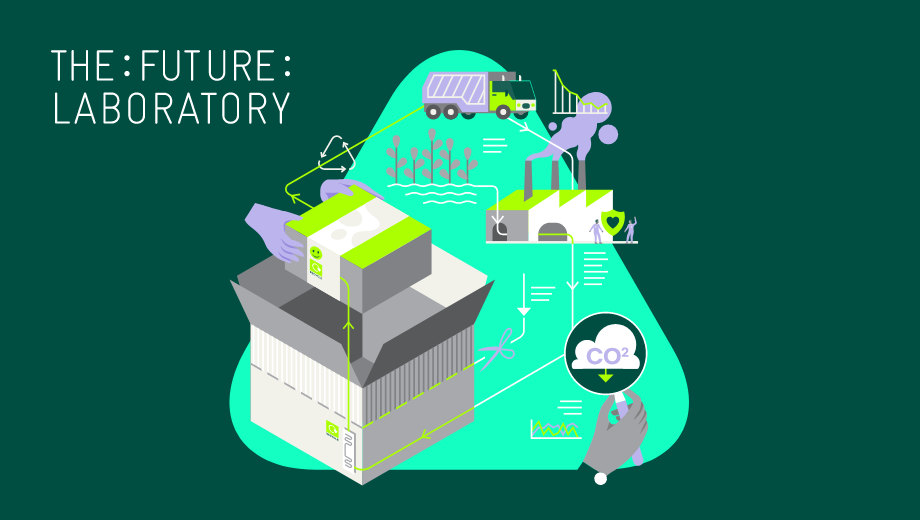

Digitize at speed and scale. Now is the time for bold moves and the adoption of emerging digital technologies to digitize supply chains at scale. atma.io for example, is a new cloud platform that unlocks the power of connected products by assigning unique digital IDs to everyday items, providing end-to-end transparency by tracking, storing and managing all the events associated with each individual product. The use of digital identity technologies can improve customer experiences, lower operational costs, dramatically reduce waste through higher inventory accuracy, minimize cross-organizational friction, authenticate products, and enable circularity. It’s a win-win situation and these technologies can be expected to play an increasing role in modern, resilient and sustainable supply chains.

Invest for business value. To unlock the power of digital transformation it must be embedded in a company’s digital strategy with clear financial and operational-performance metrics in place. Alignment with real business needs and your sustainability strategy will ensure adoption across your organization. The business case for digitizing supply chains is compelling and well-documented. In a recent survey by Cognizant, 77% of respondents "list environmental sensors and IoT as important or very important to meeting their sustainability goals.” RFID technology can bring inventory accuracy up to 99%, increasing the speed of everyday processes and reducing problems with inventory, stock shortages and waste. In the apparel industry alone, RFID has proven to reduce apparel inventories by 2-13% while at the same time providing a sales lift of 1.5-5.5%2. Furthermore, the risk of not tackling supply chain transparency issues is clear. The CDP, a not-for-profit charity that runs the global disclosure system for investors, companies, cities, states and regions, reports that companies are facing up to US$120 billion in costs from environmental risks in their supply chains within the next 5 years.

Understand supply chain decarbonization. To meet the urgency of curbing climate change, it is critical that businesses act to eliminate greenhouse gas (GHG) emissions. Supply chains represent a great opportunity to decarbonize and meet net-zero pledges and the technology that is needed to significantly reduce emissions is readily available. Avery Dennison is working with many brands and retailers, including a global sportswear brand, to track billions of items at an item-level to build a meaningful picture of the total product lifecycle emissions of individual products. When we consider industries such as logistics and transport, or food supply chains which account for 26% of all GHG emissions, the possibilities are huge and the supply chain’s role in decarbonization could be an absolute game-changer.

I am both confident and hopeful that we will see increased momentum in the coming months as regulatory, commercial and consumer pressure mounts. We've already started to see this happen with Shell recently ordered that by 2030 they must reduce supply chain emissions by 45%. Forward-thinking leaders know that it’s no longer enough to dip their toes in the waters of digitization, what’s needed is a whole system transformation of supply chains if we want business and the planet to thrive.