Founded in 1988, American Nuts began in a small facility of just 10,000 square feet. As customers became aware of their quality products, commitment to excellence, and dedication to offering a variety of services, the company grew quickly – from peanut to coconut size, figuratively speaking. Today, American Nuts runs operations in five facilities in California and Ohio and has become one of the largest nut processors in North America.

To combine the ongoing commitment to excellence with a healthy dose of profitability, American Nuts wanted to better control their business in the areas of inventory / warehousing, operations / production and quality management.

Similar to many manufacturing companies, American Nuts was using a well-known ERP system, but similar to other traditional systems, inventory data accuracy was not practical to achieve, so they started to consider leveraging other technologies to address their most pressing concerns. Besides inventory accuracy, American Nuts was looking to computerize all aspects of operations including shop floor controls, warehouse management, production scheduling, quality control management, centralized communication system, real-time alerts and data analytics.

After much research they learned that none of the available solutions had a complete all-in-one package to accommodate all of their needs, and especially nothing with automated real-time capabilities, until they came across Senitron’s ERC RFID system specifically designed to tackle complex manufacturing challenges and workflow requirements.

Immediately after the meeting and demonstration of Senitron’s ERC RFID system, American Nuts realized that this was the perfect solution they were looking for. The CEO, CFO, and top operations management were simply amazed to see how this system was built to address the pain-points they had been facing, and unanimously approved the deployment of the ERC solution.

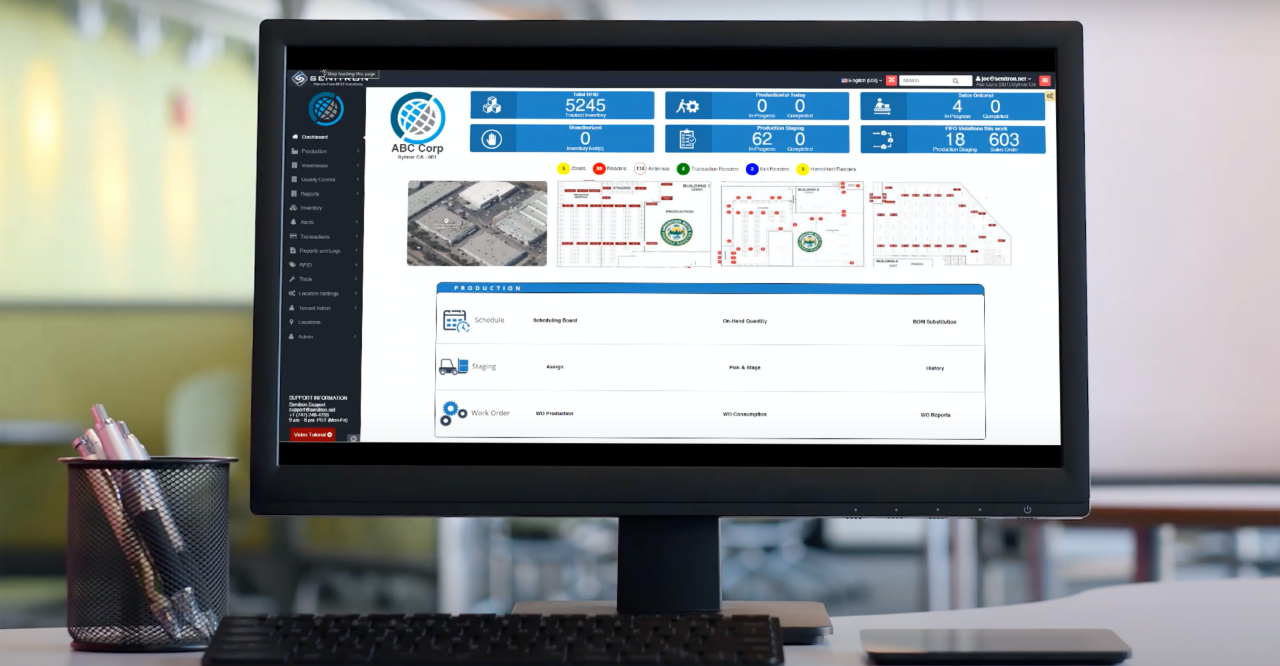

Though RFID tracking is nothing new and has been around for many years, Senitron’s ERC solution stands out by combining RFID with proprietary software resulting in an entire manufacturing facility using ERC’s unified platform to transact every action. From the personnel on the warehouse floor receiving purchase orders in ERC and applying Avery Dennison’s AD-665u8 products (performing exceptionally well in a wide array of applications and across a broad range of dielectrics) to the production managers scheduling productions in the ERC scheduler, the sales team checking RFID real-time inventory, order fulfillment crew using ERC to locate, pick and ship inventory, all the way to upper management being able to observe, analyze and make informative business decisions using ERC’s management dashboard.