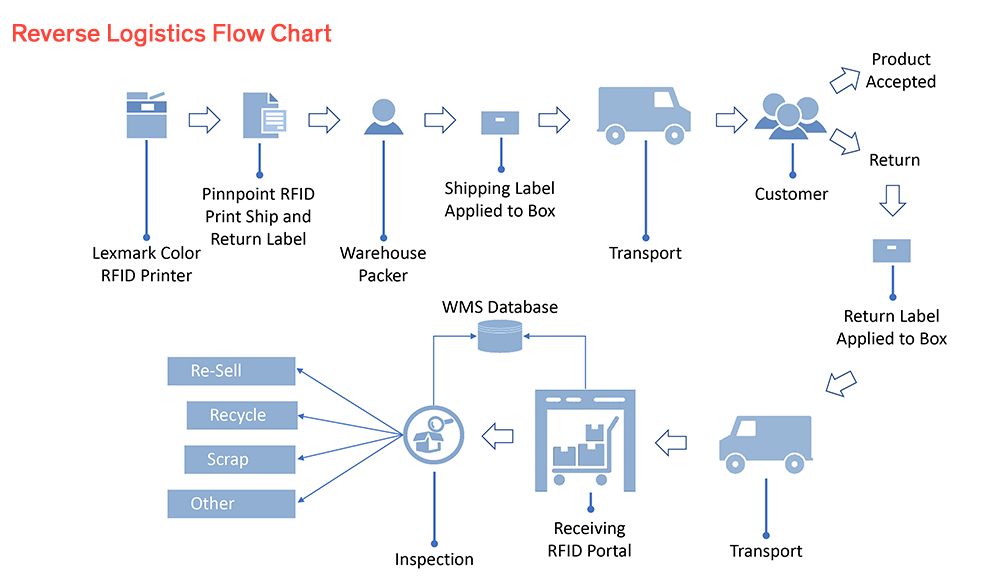

Selling online has its slight downside: dealing with the return of shipped goods. Smartrac’s global market partner, Pinnpoint, recently introduced a new solution using Lexmark’s intelligent RFID devices (printer/MFP) that can revolutionize reverse logistics for online e-commerce distribution.

The reverse logistics market is defined by product brands, logistics providers and retailers that increasingly must deal with the return of shipped goods. In many cases, companies ship multiple product options to their customers who then make their selection and send the unwanted products back. This customer service return process option is crucial for obtaining new sales, however, this option puts pressure on the logistics of the retailer. It can create a massive return product inventory backlog as items wait to be returned to the warehouse shelves.

Drastically improving the handling of returned goods

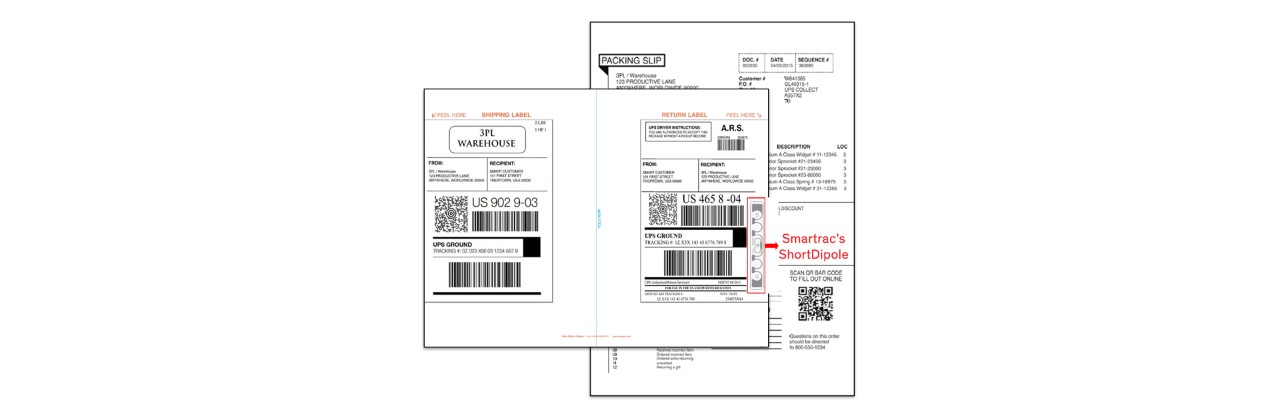

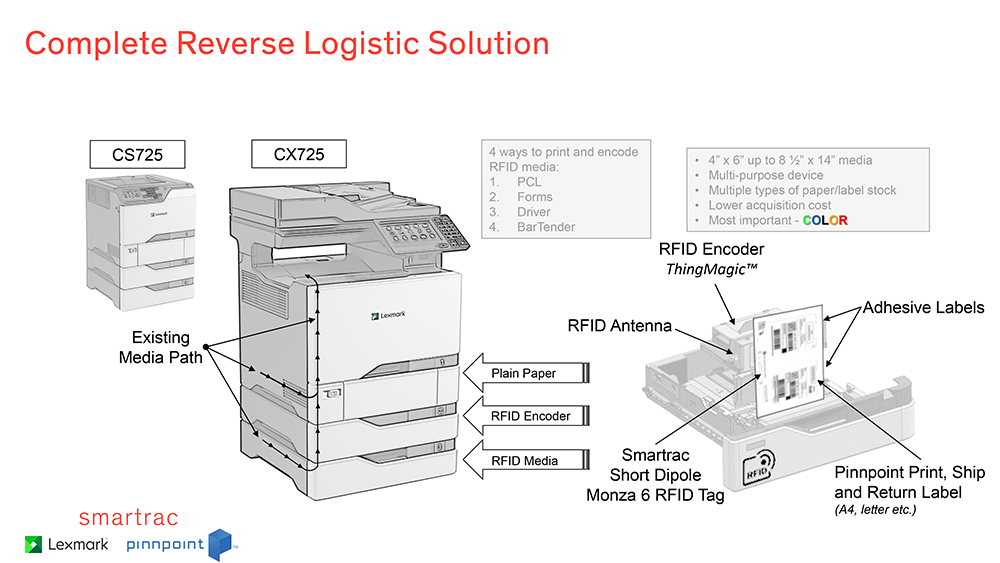

There is, however, a better way. By providing a customized, RFID-tagged return shipping label with every outgoing shipment, a brand owner or retailer can ensure that returned goods can be checked in automatically using the appropriate reader infrastructure. Thus, they gain a comprehensive and real-time overview of all returned goods, as well as a reduction in labor hours and associated costs. In addition, the products can go back into inventory much more quickly, making them available for sale again sooner than with older methods.

To achieve these benefits, Pinnpoint, a Sweden-based logistics solutions specialist, provides off-the-shelf labels for use in Lexmark’s new RFID-enabled devices, as well as offering a full solution consisting of software and integration services. The labels - typically sheets of A4, A5 or customized formats - embedded with RFID tags from Smartrac, are designed to be affixed to cartons or shipping containers being shipped to a customer.