Meanwhile, in the world of heavy industry, a major shipbuilder in Asia has deployed Midas FlagTag to help cope with the millions of unique metal parts used in the construction of a ship - everything from steel pipes to metal bars, plates, fittings, fasteners, etc.

While the effective and efficient tracking of all these parts is critical for project success, efficiency and safety, the use of RFID has not been possible to date due to cost and performance issues.

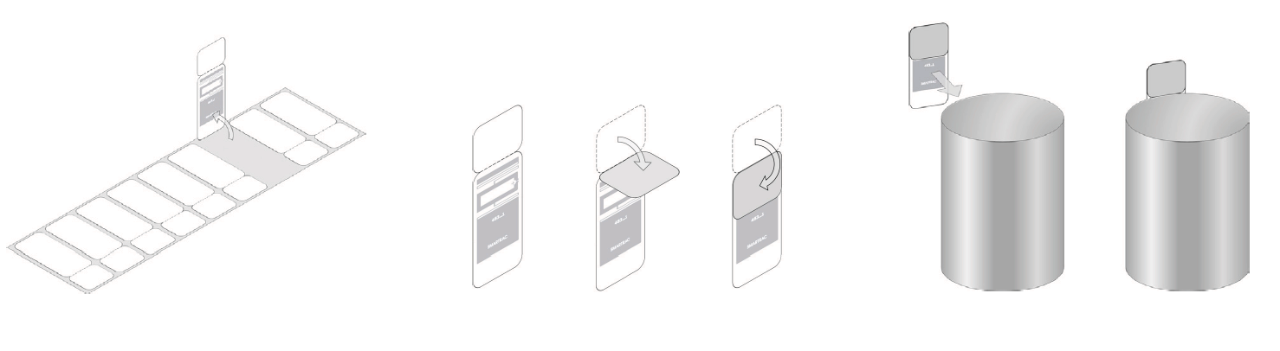

Midas FlagTag uses the geometry of the metal parts themselves to boost RFID performance, and is able to achieve 100% read success for metallic items randomly stacked on a pallet or inside a crate, with both gantry-mounted and handheld RFID readers. This solution offers significant efficiency gains for complex industrial operations where vast numbers of metallic items need to be managed, accounted for and tracked effectively.

Advanced technology and enhanced connectivity

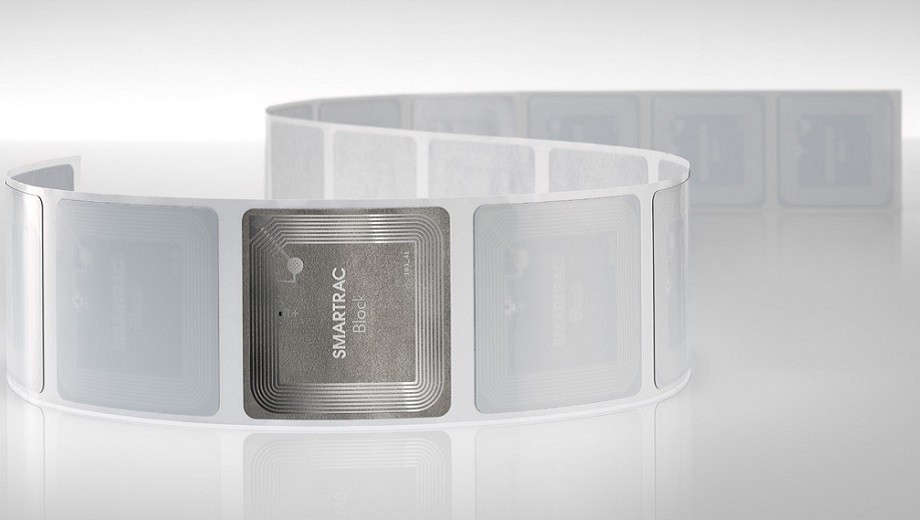

Smartrac’s Midas FlagTag is equipped with the Impinj Monza R6 IC that features an Autotune function, which helps Midas FlagTag to work at peak efficiency, even in rapidly changing environments. Furthermore, the Monza R6 chip offers unique TID, enabling pre-serialized EPC, and is 100% performance tested.

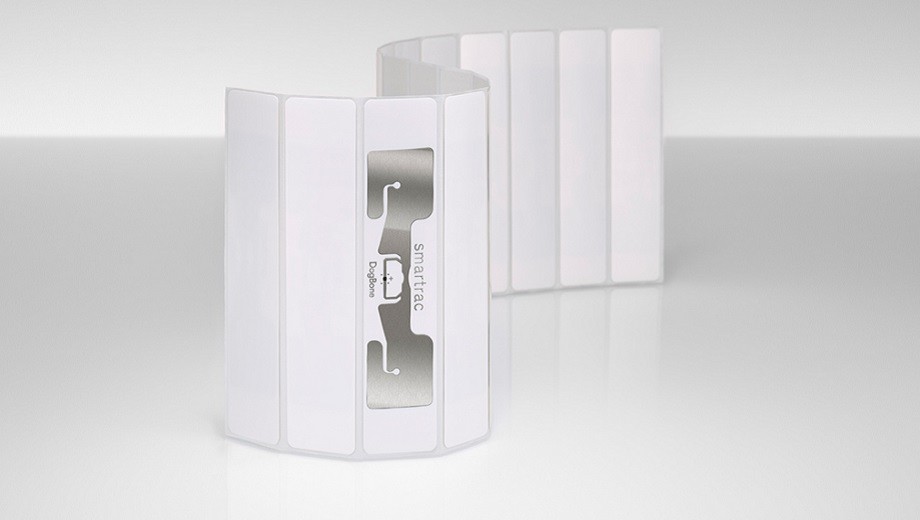

Midas FlagTag products utilize RAIN RFID technology, based on the UHF RFID protocol standard developed by GS1 and ISO. The tags are compatible with RFID printers for easy printing and encoding.