After the RFID tags were installed on each individual bottle, supply-chain visualization began. The goal is to use digital technology to track the supply chain from the brewery to the liquor stores, making it possible to visualize in real time the flow of goods: when, where, and what.

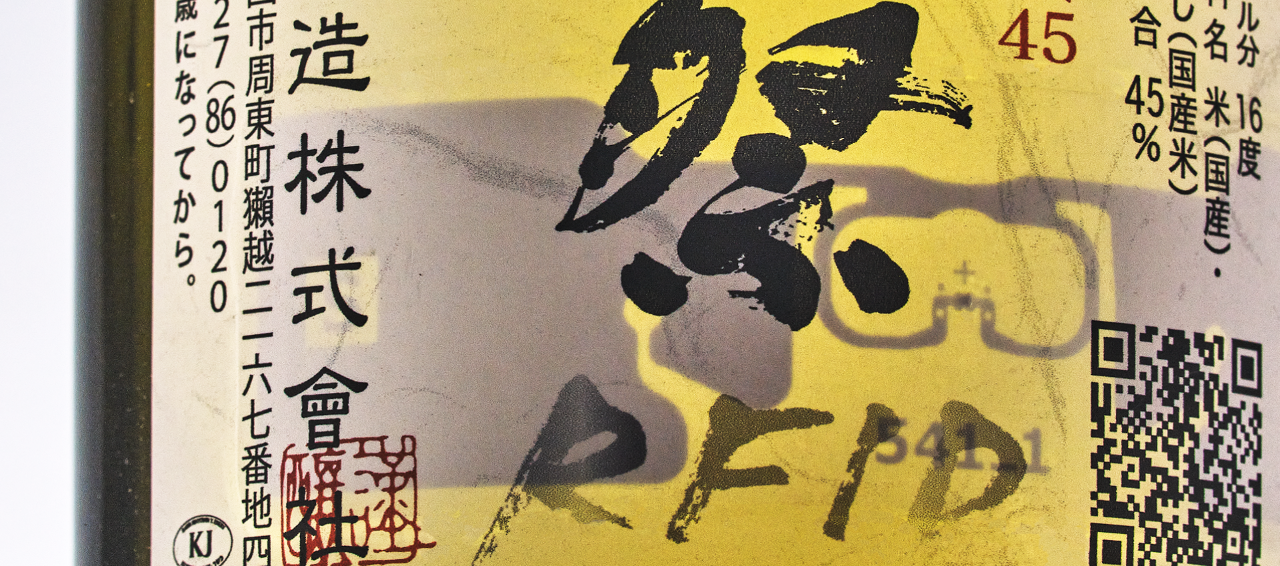

In order to facilitate tracking during the distribution process after shipment, Asahi Shuzo associated the unique IDs on the 12 bottles with an RFID tag on the case in which they were packed. In this way, it is possible to track the distribution process of each bottle by simply reading the RFID on the case, rather than having to read the RFID on all 12 bottles after they leave the brewery.

The RFID tag on the case also has a QR code printed on it, so that wholesalers and liquor stores that do not have RFID readers can use their smartphones to read the QR code and carry out the bottle receiving and shipping process.

In this way, brewers can now monitor whether their products are being properly managed and sold in their intended retail channels. At the same time, consumers can now instantly access information such as “when was this sake made?” and “how long has this sake been sold at liquor stores?”

Ichiro Abe, Senior Consultant at Mizuho Research & Technologies, who was in charge of the project, commented “Avery Dennison Smartrac is a top global company, and we were very pleased with their solution.” The consultant also said “Generally, RFID is perceived as a way to save labor in business operations, but I feel it is necessary to promote RFID as a system that achieves total optimization not only for manufacturers, but also for retailers and consumers.”

This project reaffirmed the need to select a partner that can propose appropriate solutions based on experience and understanding of the issues faced by the customer, and who has the knowledge to implement high-performance products in line with the customer’s strategy, in order to successfully implement RFID.