3. Can you give practical examples for RFID use for sustainability?

By embedding RFID tags in products, we can track not just their journey from production to purchase, but also gather and share crucial environmental data.

RFID labels can carry logistical information, product information but also CO2 footprint of the product journey and information guiding them to the right waste stream.

For textile brands, RFID can enable them to track jeans from factory to store and years later to the textile sorting facility for recycling.

To achieve a world free of plastic, the reuse of products is accelerated. RFID can help to increase the return rate.

4. Reducing waste is such a challenge for companies. How does RFID help solve this?

Using the RFID technology to improve the visibility of company stocks is helping to reduce overstocks or wrong purchase decisions. As a consequence it is functioning as carbon avoidance for the retailers and brand owners.

5. Is AD Smartrac working with new technologies to substitute the metal antenna of the tags by an antenna made of special inks to reduce the carbon footprint?

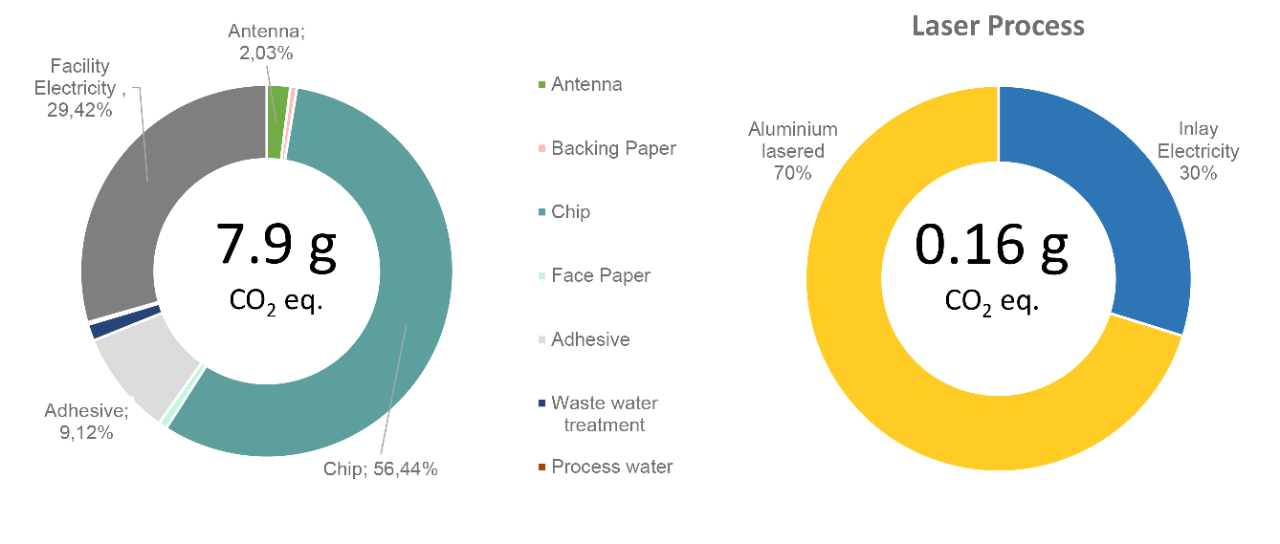

Most of our RFID inlay products today have antennas which are die-cut or laser-cut on a variety of carrier materials .

According to a study by an independent Life Cycle Analysis (LCA), the die-cut and laser-cut manufacturing method results in 70-90% savings in the carbon footprint, compared to traditional etching methods.

Antenna carrier materials include papers, plastics, fabrics and an ever evolving list of materials, leveraging our Avery Dennison materials expertise.

We are also constantly developing new technologies and bringing new sustainable and innovative products to the market.

6. Is RFID able to influence consumer behavior towards more sustainable practices?

By extending the use of RFID beyond the point of sales in retail, the data can be used to connect with consumers. Digital technology empowers consumers to make informed choices from the shop-floor till the end of the product's life.

By tagging bins, waste items, municipalities can gain valuable insights into waste patterns. This data can then be used to improve recycling processes, manage waste collection routes and influence consumer behavior towards more sustainable practices.

7. How do you see circularity in the case of rubber products? Tires, Belts, e.g.

The end of life for tires and belts are valuable material resources for the circular economy. Rubber is a significant component but it is only a small part of the passenger vehicle. Materials like synthetic polymers, steel and textiles also play a part in car components that are a valuable resource to be recycled to be used again.

Avery Dennison has released several RFID labels specialized for Tire tagging, including the Maxdura Tire tag. We are happy to present this at your convenience.

8. PET free RFID labels, is this something which is being requested and asked for?

Yes, we see an increasing demand for PET free labels - especially for single use products. It is not for all applications but many, for example within Apparel.

The reduction in CO2 is significant, together with improvements in general in the production process, one can save up to 80 and even 90% of the CO2 footprint. We will continue to launch our Pure products, which are pricing equal to non Pure.

At this moment we have released the following RFID labels in 100% Pure (non plastic) variants: Miniweb, Belt, Dogbone, Web and Midas Flagtag.

9. Is AD Pure™ a true innovation (new innovation) or is this a sustainable version of an existing product?

The AD Pure™ and AD Pure 95™ are sustainable versions of existing products. Manufacturing of the AD Pure™ products requires new types of materials and innovative technologies.

In the AD Pure™ development pipeline there are several products under development, more information can be found on our website.

10. Where can I find the presentation that was presented during the webinar on 31st of January 2024?

The presentation is made available via this pdf link

For more information and requests related to sustainability, please contact your Avery Dennison Smartrac contact.