RFID hard tags are often used in very demanding industrial and logistical applications that require ultimate performance and quality. To achieve this, Smartrac's R&D and manufacturing facility in Wehnrath, Germany, the company’s competence center for hard tags, has invested in a high-tech anechoic test chamber.

From the perspective of a non-engineer, the testing space is basically a windowless room that is shielded from radio waves by steel layers on the walls and ceilings, and accommodates RAIN-RFID (UHF) readers and transponders for testing. It provides connections to numerous measurement instruments outside the chamber and is equipped with specialized interior fittings consisting of pyramid-shaped microwave absorbers. These visually striking items cancel the reflections (echoes) inherent to electromagnetic waves, which would disturb any precise measurement in a normal environment.

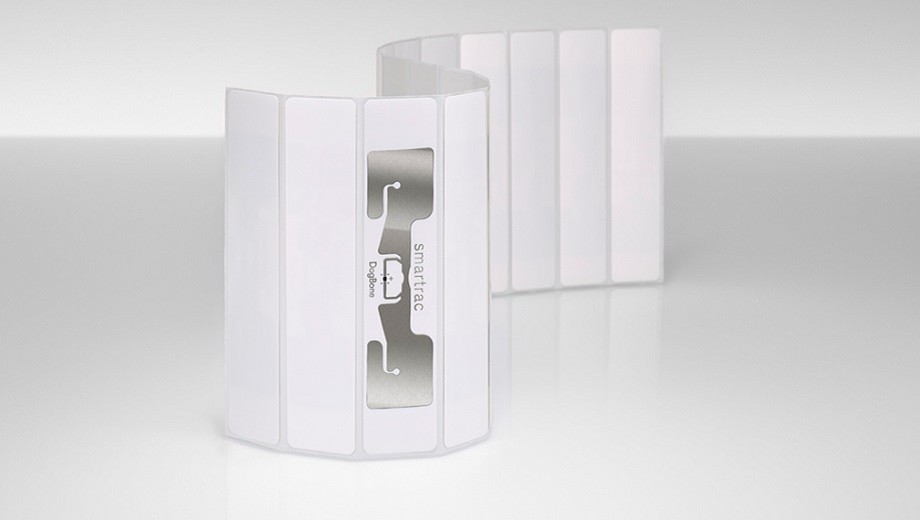

Suitable for all UHF transponder form factors and sizes

In this context, it doesn’t matter if the test object is a simple RFID inlay, a converted tag or a hard tag, be it in prototype, special test sample or volume production form. Due to its spatial extent, the anechoic chamber is also -- beyond transponder characterization -- well suited to measuring conventional antennas. Testing procedures can be performed for all international UHF frequency bands, explicitly including those that aren’t used for commercial purposes in Europe. To make the facility future-proof, the entire interior design and measuring devices also allow testing in frequencies of up to 11 GHz – also particularly suitable for the upcoming, innovative Super-High Frequency equipment.

Room for improvement –literally!

The size of a very spacious living room (8x4x3m/24x12x9ft), and representing a six-figure investment, the test chamber allows for the testing of the read characteristics and performance of RFID transponders of any kind and any size. Given that even the largest Smartrac products hardly exceed the dimensions of a deck of cards, DVD cover or sheet of letter paper, the measurements of the chamber seem pretty big at first glance. However, at least two factors justify its size. Firstly, ideal testing conditions only exist in a small area at the center of the chamber -- called the “quiet zone” -- in which the amplitude and phase of antenna radiation are near-constant. Secondly, for valid and relevant testing of application scenarios, not only the transponders have to fit in that quiet zone, but also the items they are typically attached to.