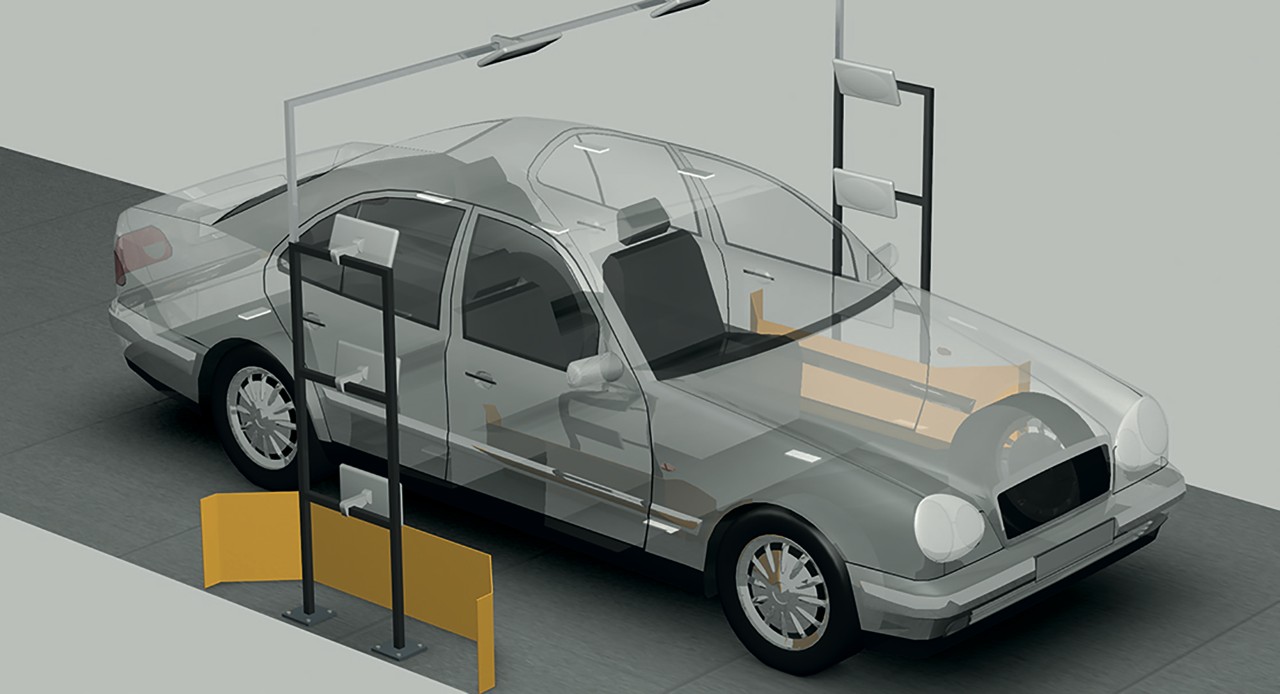

Before the vehicle is driven into the rain spray chamber as part of the final inspection, it first of all goes through an RFID gate which registers all the tags. After the spraying process, the car goes through a second RFID gate at the exit, which in turn reads in all the tag data.

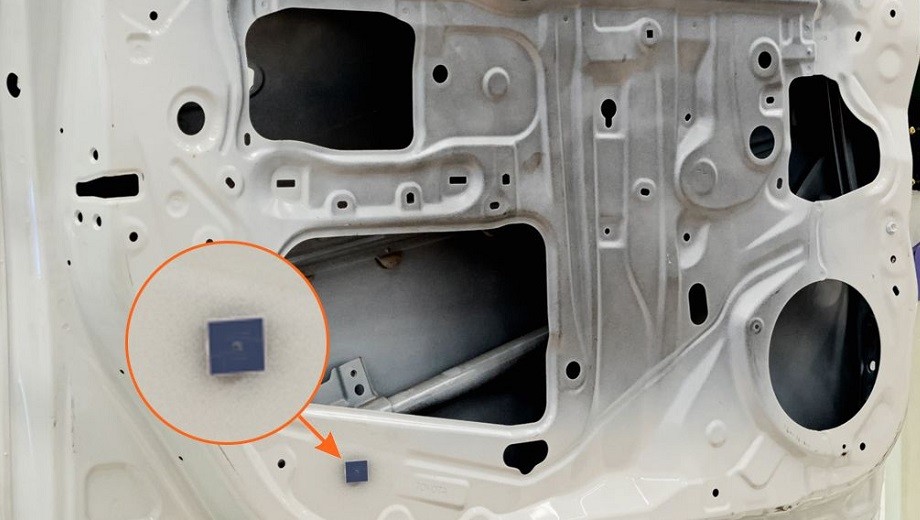

The passive UHF-RFID sensor tag (Sensor Tadpole) can be stuck directly on metal and later also read in positions that are difficult to access in spite of the surrounding structures of the vehicle. Thanks to this capability and its compact format of 21.5 x 73 mm, the self-adhesive sensor tag can be mounted without any problem at many points in the car body.

If areas have to be monitored where direct mounting is not possible, tag variants with extension strips are available in different lengths. The water reaches the tag via the extension even from places that are otherwise inaccessible.

If the tag detects humidity, it reacts with a change in impedance, which is registered by the RFID read/write heads in the gates. A powerful evaluation software enables the affected point in the vehicle to be localized precisely by means of the collected data.

In Europe the tag works in the 865 to 868 MHz frequency range. Being a passive RFID sensor tag, it does not require a power supply and can remain in the car for its entire lifetime so that it can be read again at any time. The tag draws the required energy from a handheld or the read/write heads of the gates.

To get more information on leakage testing in automobile production click here.

For information, please contact our Sales & Customer Service Team.