Robust tire tag is embedded for life

Industry segment: Automotive, Industrial Applications

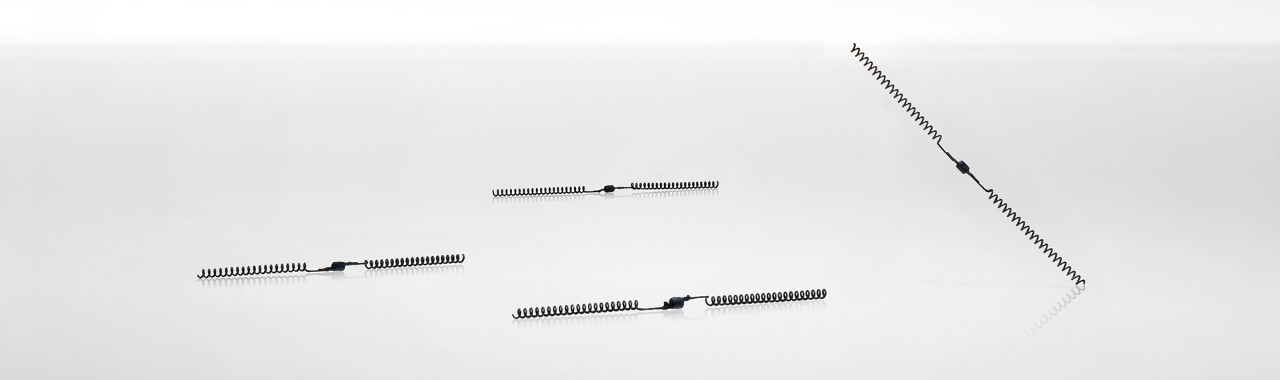

An embedded UHF tire tag is intended to be integrated into the tire mold prior to the manufacture and curing of the tire. It is attached to the tire directly, during tire vulcanization, so that it can be fully connected to the core of the tire and function correctly to track the tire. The use of an embedded tire tag controls the complete lifecycle of the tire from production to recycling (environment control). It supports maintenance recording, inventory tracking and fleet management, and facilitates several additional different business models. Being exposed to harsh environmental conditions during the manufacturing process as well as on the road, an RFID tire tag needs to be robust. Avery Dennison Smartrac ́s AD Maxdura® Tire Tag uses an automatic overmolding and resistance welding method to ensure highly durable and uniform antenna connections.

Typically, the IC module of common tire tag products is a small printed circuit board larger than the diameter of the spring antenna. However, tire manufacturers nowadays require much smaller dimensions to maximize homogeneity within the tire composites. To reduce overall dimensions, the AD Maxdura® Tire Tag is built up with a customized IC housing based on lead frame technology.

One of the most challenging issues is the adjustment of the antenna’s resonance frequency when the tag is embedded inside the tire. As every customer uses its own specific rubber compound, the antenna length needs to be tailored to the specific material properties. As one of the leading automotive suppliers of RFID solutions, we have more than 20 years’ experience in the field. We have leveraged our strong experience in designing RFID products for the world’s largest car manufacturers to develop the AD Maxdura® Tire Tag.