Would you like to ensure the successful launch of your RFID implementation? With On Metal Tag, Smartrac’s new, on-anything tag, it’s easy. On Metal Tag works on any surface, and performance variation has been minimized using an innovative structure that makes On Metal Tag the thinnest printable UHF on-anything tag ever. It has never been easier to be an RFID expert.

On Metal Tag is a new product from Smartrac that provides the thinnest printable solution ever for tagging metal objects and surfaces, as well as challenging non-metal objects.

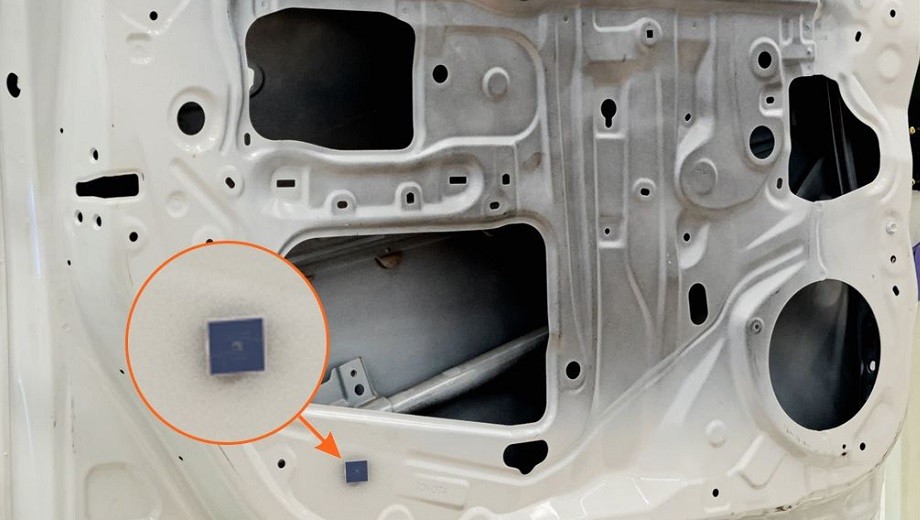

The product is ideal for tagging metal objects, such as fire extinguishers, car parts, scaffolding, steel pallets, trolleys, beer kegs, water, gas and oil pipes, metal cabinets, machine parts, power and assembly line tools. It is also a great solution for tagging difficult non-metallic items, such as liquid canisters/containers, paint pails and high-detuning surfaces. This printable, on-metal tag enables applications that were not possible earlier with traditional UHF inlays, and offers the possibility to print and encode the product with standard RFID printers on-site, which can reduce project costs dramatically.

On Metal Tag is available for use with both ETSI and FCC frequencies (865-868 MHz for Europe, and 902-928 MHz for the Americas and Asia). The solution’s ultra-thin form factor makes it extremely easy to print on: it can be encoded and printed on standard RFID printers, and also features a printable face material, which is usable by thermal transfer printers.

The tag features an Impinj Monza 4QT integrated circuit with a 512-bit user memory, and the transponder is die-cut and laminated with white PET 50. The air interface uses the EPC Class 1 Gen 2, ISO 18000-6C protocol. Two versions of the product are currently available: the first with aggressive RA-4 adhesive, and the second without adhesive. This second, dry version has been developed to fulfill the requirements of converters.

Best-in-class features

Smartrac’s market-leading design and fabrication expertise has produced the thinnest UHF on-metal tag available today, which not only protects the print heads of RFID printers, but also ensures optimum converting properties and usability. The tag’s thin, soft, flexible structure means it is ideally suited for use on curved as well as flat surfaces.

Only 0.6 mm thick, On Metal Tag nonetheless offers a read range on metal of up to 3.5 meters. The dry product is only 0.58 mm thick, which opens huge opportunities for converters to create attractive solution for end users. For example, such a thin product could easily be placed inside layered structures and between stacked items.

The product is delivered as a single-row, 500-unit reel. A clean gap between the tags makes it user-friendly, suitable for automated applicators, and minimizes waste at the point of use. Tight quality control ensures reliable performance, and minimized performance variation between production lots. Smartrac, as a global market leader, offers good product availability and an agile supply chain, as well as mass volume pricing.